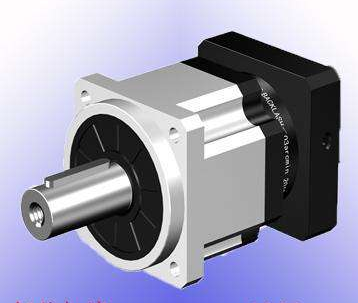

Servo motor reducer is an indispensable part of industrial production equipment. Only correct installation, use and maintenance can ensure the normal operation of the machine. When installing the reducer, please use the correct method.The next step is the correct installation method of the servo motor reducer organized by the editor for everyone. Come and watch.

1. Before installation, confirm whether the motor and reducer are intact, and strictly check whether the dimensions of the parts connecting the motor and the reducer are matched. Here are the dimensions and tolerances of the positioning boss of the motor, the input shaft and the groove of the reducer.Before installation, wipe off the anti-rust oil on the motor input shaft, positioning boss and the connection part of the reducer with gasoline or zinc-sodium water.Its purpose is to ensure the tightness of the connection and the flexibility of operation, and to prevent unnecessary wear.Before connecting the motor to the reducer, the keyway of the motor shaft should be perpendicular to the tightening bolt.To ensure uniform force, first screw on the mounting bolts at any diagonal position, but do not tighten, then screw on the other two diagonal mounting bolts, and finally tighten the four mounting bolts one by one.Finally, tighten the tightening bolts.

2. Unscrew the screw on the dust-proof hole on the outer side of the reducer flange, adjust the PCS system clamping ring to align the side hole with the dust-proof hole, and insert the inner hexagon to tighten.After that, remove the motor shaft key.The third step is to connect the motor and the reducer naturally.When connecting, it must be ensured that the concentricity of the output shaft of the reducer and the input shaft of the motor is the same, and the outer flanges of the two are parallel.If the center is inconsistent, it will cause the motor shaft to break or the gear of the reducer to wear.In addition, during installation, it is strictly forbidden to hit with a hammer, etc., to prevent excessive axial or radial force from damaging the bearings or gears.

Through the introduction of the above article, everyone has now understood the installation method of the servo motor reducer. Only the correct installation of the servo motor reducer can ensure the normal operation of the production equipment.At present, my country's industrial level has reached the world's advanced level. This is an inevitable trend of technological development. Thank you for reading.